Delivering Energy and Heat When You Need It

Keeping natural gas safe, affordable and reliable is our focus at Nicor Gas every day. We purchase natural gas during the summer months when it is normally less expensive and store it for use throughout the year. This helps keep winter heating costs down and our year-round supply up. These purchasing strategies, coupled with our underground storage facilities, ensure that our 2.2 million customers receive competitively priced service and dependable energy and heat.

We never stop supplying our customers, even during incredibly high demand events like extreme weather. During the 2019 Polar Vortex, Nicor delivered more than 4.8 billion cubic feet of natural gas, and no one lost heat due to curtailment. Without the added capacity of our underground storage, more than 700,000 customers would have been without heat during the dangerously cold temperatures.

These incredible engineering feats are only possible through the use of storage facilities. Without these critical reserves, it would be impossible to continue providing clean, safe, reliable and affordable natural gas to those who depend on it year-round.

How does Underground Storage Work?

Underground storage facilities are a safe and widespread practice. The United States Energy Information Administration (EIA) reports that throughout the U.S. there are currently more than 400 such facilities ready to meet demand. Nicor Gas developed and operates eight of these fields in Illinois to meet customers’ energy demands.

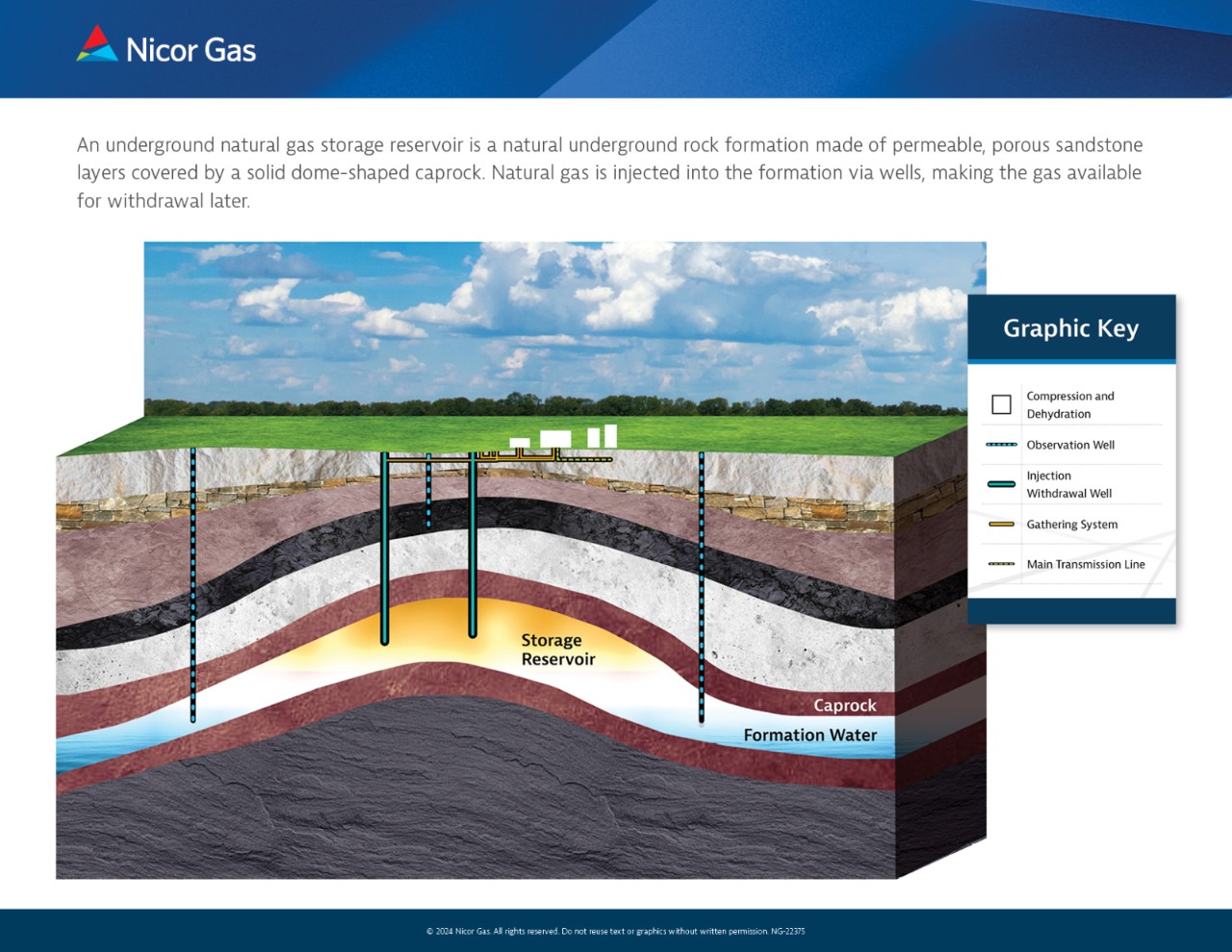

An underground aquifer reservoir is a natural underground formation made of porous sandstone layers covered by a solid dome-shaped caprock.

We inject natural gas via deep wells that vary from 800 feet in northern Illinois to 3,700 feet in our southern fields. The dome shape of the overlying caprock holds the natural gas until it is needed during winter operations. To remove gas and send it on to our customers, gas must be at higher pressures than the transmission pipeline for it to flow into the system. At some fields, the gas is already at that higher pressure. At others, gas must be pumped into the transmission line. The gas is dehydrated to remove water vapor before it starts being distributed.

Here, our storage expert Joe Deters takes you around two of our storage facilities:

Storage & Peaking Operations

Safety

Nicor Gas takes seriously the commitment to safely storing and delivering natural gas. We manage our facilities with the highest of integrity and transparency, employing dedicated teams of experts in the storage and maintenance of natural gas and working with multiple regulatory bodies. Our safety training and operating standards are rigorous and extensive. That’s because nothing is more important than the safety of our customers and communities.

Each one of our storage facilities receives oversight, audits and inspections from the Occupational Safety and Health Administration (OSHA), Illinois Department of Natural Resources (IDNR), Illinois Environmental Protection Agency (IEPA), Illinois Commerce Commission (ICC) and from the United States Pipeline and Hazardous Materials Safety Administration (PHMSA), which establishes national policy and sets and enforces standards for facilities and pipelines.

Just as safety is our priority, so is compliance. We meet or exceed requirements including Federal, State, and local environmental regulations. We are 100% committed to environmental compliance and conduct routine and extensive self-monitoring, in addition to our responsibility to regularly sample, monitor and report findings to the Illinois Environmental Protection Agency (IEPA) as a requirement of our permits.

We are dedicated to ensuring the safety of our communities through continuous improvements of our facilities with upgrades and new technology. We work closely with local leadership and regulators at all levels of government to continue our strong history of safely supplying affordable, reliable natural gas to all.

Nicor’s History Storing Natural Gas

When Nicor Gas first began storage operations, natural gas was safely held in low-pressure, above-ground tanks and interconnected high-pressure cylinders buried beneath the surface. In 1954, a pipeline supplier developed the state's first underground facility near Herscher, just southwest of Kankakee. We shared that valuable storage capacity with other distributors, but as our customer base and services expanded, we recognized the need for our own storage fields. In 1957, we found a potential geologic site in Illinois. After extensive testing, regulatory permitting and oversight, the location was approved and the first cubic foot of gas was injected in 1958 with the goal to provide reserves for the 1960-61 heating season. Over the years we developed seven additional state-of-the-art facilities to safely and reliably deliver clean, affordable natural gas to our customers.

FAQ

How much natural gas in stored in facilities across Illinois each year?

Nicor Gas has a total combined 150 billion cubic feet of annual storage capacity across eight underground storage facilities: Troy Grove, Ancona, Pontiac-Mt. Simon, Pontiac-Galesville, Lake Bloomington, Hudson, Lexington and Pecatonica.

How much does storage support your winter delivery?

Storage supplies one-third of our normal winter deliveries. During the 2019 Polar Vortex, we safely delivered a record-setting 4.8 billion cubic feet of natural gas to customers in a single day, ensuring reliable access to heat through sub-zero temperatures. Without natural gas storage, more than 825,000 customers would have been without heat during this dangerous and extreme weather.

Are underground storage facilities safe?

Yes. Nicor Gas is committed to ensuring the safety of our communities through continuous monitoring and improvement, infrastructure upgrades and the installation of new technologies. Our teams of dedicated storage engineers work with regulatory agencies to oversee the safety and maintenance of our natural gas facilities.

Does Nicor Gas operate the underground storage fields to profit from lower natural gas prices?

No. Our natural gas storage systems are a critical safety net to protect against price fluctuations in supply and demand for gas. We’re able to buy gas for customers when prices are low, store it for later use and pass those savings directly to our customers.